|

Binh Khi Branch (CNBK) is a subsidiary of PetroVietnam Southern Gas Joint Stock Company (PVGas South), established in 2006 with an initial investment of USD 5.5 million, a production capacity of up to 1 million LPG cylinders per year, located on a 30,000 m² site on D3 Road, Vinatex-Tan Tao Industrial Park, Hiep Phuoc Town, Nhon Trach District, Dong Nai Province—a location with convenient inland waterway and road transportation for domestic and export logistics. Its main business activities include:

- Manufacturing new LPG cylinders with capacities from 06kg to 48kg according to standards QCVN 04/BCT, DOT 4BA 240, EN 1442: 2017, and ISO 4706: 2008, under the supervision of independent agencies such as Hartford Steam Boiler (USA), Bureau Veritas (France), and the Region II Center for Technical Safety Inspection of Vietnam;

- Maintenance, repainting, and inspection services for all types of LPG cylinders.

Over 12 years of development, CNBK has continuously innovated, invested in expansion, and enhanced product quality and human resources to become a leading unit in Vietnam and the region in LPG cylinder manufacturing. The factory's production lines are modern, fully synchronized, with more than 80% automation, and have delivered over 10 million safe, high-quality products to the market, earning consistent trust from customers. To achieve these values, CNBK has developed and implemented the following criteria into its operations:

- First, input material quality is strictly controlled before production. Main materials such as steel, valves, welding materials, and zinc are supplied by reputable manufacturers from Nippon and JFE (Japan), Posco and Hyundai (South Korea), and Cavagna and SCG (Thailand);

- Second, a detailed quality control system is established and strictly adhered to at each production stage, with a laboratory equipped with modern, highly accurate, and reliable devices to meet both domestic and international technical standards;

- Third, the workforce is professionally trained, especially technical production staff such as welders, testing personnel, QAQC staff, who are trained and maintain international certificates under ASME and ISO 9712;

- Fourth, CNBK pioneers in applying science and technology in production and enterprise management. All planning, production deployment, supervision and operation, quality control, and delivery processes are executed using dedicated enterprise resource planning software (ERP);

- Lastly, an integrated management system for Quality - Health - Safety - Environment (QHSE) following ISO 9001: 2015, ISO 14000: 2015, and OHSAS 18001: 2007 has been established and fully implemented with the goal of maximizing customer satisfaction in quality and service, creating a safe working environment for all employees, minimizing environmental risks, and ensuring full compliance with current Vietnamese legal regulations.

|

Following its domestic success, and in the context of Vietnam’s deep integration into the global economy, CNBK has taken specific steps to bring Vietnamese products to international markets, such as:

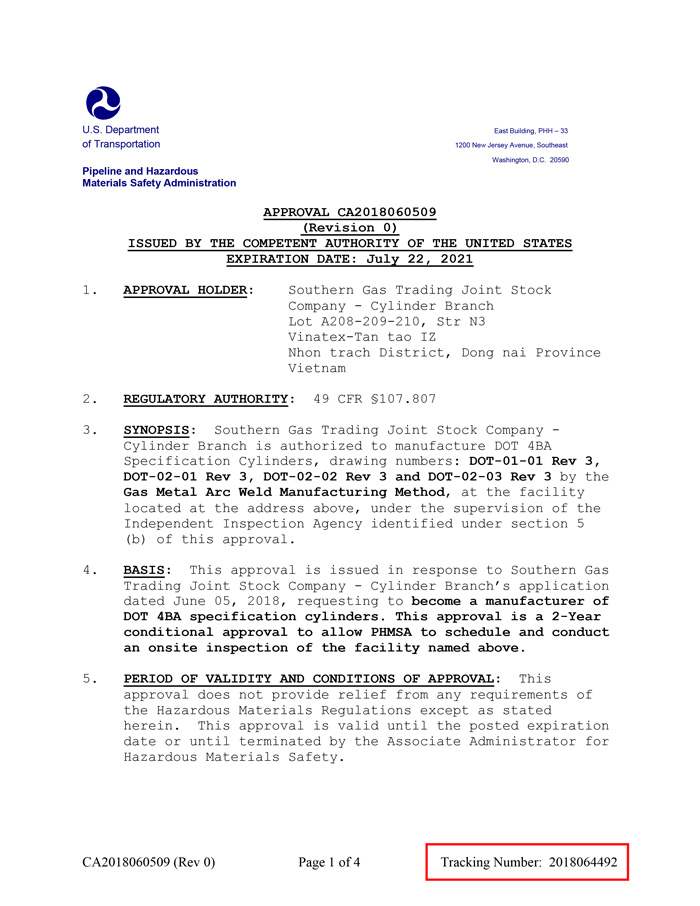

- Receiving product certification for meeting the U.S. Department of Transportation (DOT) 4BA standard, with Manufacturer Identification Number M0848, qualifying for export to the U.S. and most countries around the world;

|

Product certificate for compliance with DOT 4BA standard issued by the U.S. Department of Transportation.

- Certified by international inspection organization Bureau Veritas for its production lines meeting the strict regulations of the European Union for the manufacturing of transportable pressure equipment (TPED), compliant with European standard EN 1442: 2017 and international standard ISO 4706: 2008, allowing the product to bear PI and UN markings and qualify for export to the EU and many countries globally;

- Evaluated by Total Global Group (France) as a company with the capacity and product quality meeting technical requirements to supply LPG cylinders to Total Global across 33 countries and territories.

These certifications not only affirm that PVGas South’s LPG cylinders meet international standards and are absolutely safe for domestic retail LPG business—enhancing the PETROVIETNAM GAS brand—but also confirm the company’s competitiveness with other manufacturers in the region and globally. This demonstrates that PVGas South has secured an international passport for its products to be exported abroad, contributing alongside other Vietnamese enterprises to deeper international integration under organizations to which Vietnam is a member.