Compression fittings are essential components that offer a reliable way to join pipes or tubes seamlessly. Let’s join Gas South in this article to explore the functionality of compression fittings, their applications, and whether they are suitable for use on natural gas lines.

1. What is a compression fitting?

Compression fittings are indispensable components in plumbing and electrical conduit systems, facilitating the seamless joining of two tubes or pipes. They are particularly useful when connecting pipes of different materials, as they can be crafted from compatible materials suitable for the specific connection requirements.

Widely utilized in hydraulic, gas, and water systems, compression fittings enable the attachment of tubing to threaded components like valves and tools. Their versatility makes them ideal for various applications, including confined plumbing spaces where soldering copper pipes poses safety risks and in industrial hydraulic settings. One of the key advantages of compression fittings is their ease of disconnection and reconnection, providing convenience and flexibility in system maintenance and repairs.

Compression fittings are indispensable components

2. How do compression fittings work?

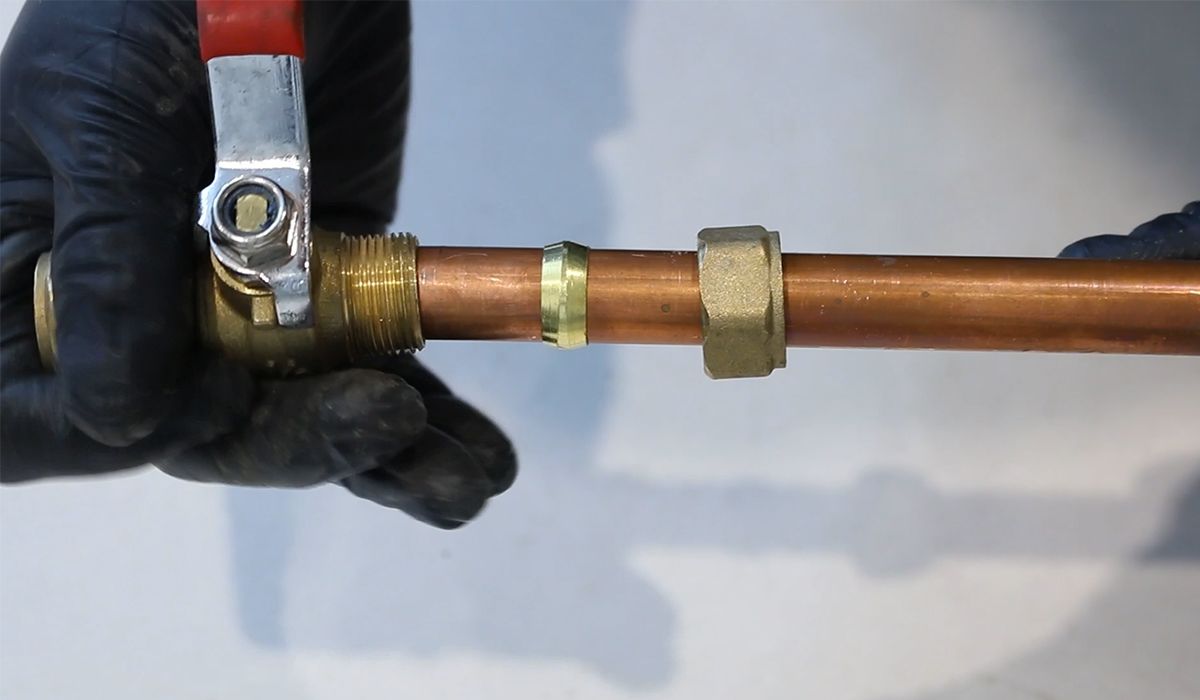

Compression fittings work by compressing a sleeve into the top of the fitting. This is achieved by tightening an outer compression nut onto the fitting's threads, usually with a wrench. As the nut is tightened, the ferrule (the little inner compression ring) compresses the sleeve, creating a tight seal between the fitting and the tubing or pipe. This compression action prevents leaks by firmly securing the connection.

The name "compression fitting" comes from the process of compressing the sleeve down into the fitting to create a seal.

3. Types of compression fittings

The compression fittings come in 2 types: the standard fitting and the flare one.

3.1. Standard Compression fittings

-

Mechanism: These fittings utilize a ferrule (also called an olive) that gets compressed between the nut and the fitting body to create a seal against the smooth outer surface of the tubing.

-

Tubing types: Standard compression fittings are commonly used with soft metal tubes like copper or aluminum due to the softer metal conforming better to the ferrule.

-

Applications: Standard compression fittings are suitable for a wide range of applications with fluids and gasses, including plumbing, refrigeration, and pneumatic systems. However, they typically have lower pressure ratings compared to flare fittings.

3.2. Flare fittings

-

Mechanism: These involve creating a flare (a cone shape) at the end of the tubing using a special tool. This flared end is then inserted into the fitting body and secured with a compression nut, creating a seal against the flared surface.

-

Tubing types: Flare fittings are typically used with soft metals like copper but can also work with harder materials like steel due to the wider sealing surface provided by the flare.

-

Applications: Flare fittings are known for their high-pressure capabilities and vibration resistance, making them ideal for applications like hydraulic systems, fuel lines, and high-pressure air lines.

4. Can you use compression fittings on natural gas lines?

Yes, compression fittings can be used on natural gas lines. Brass fittings are commonly used for low-pressure applications above ground. When using compression fittings for gas lines, it's important to ensure that they are accessible in case maintenance or repairs are needed.

For instance, when running compressed natural gas (CNG) tube lines, fire codes may require that the fittings be easily accessible, especially if they run underground for long distances. Mechanical connections may not be allowed in certain situations, so compression fittings offer a reliable alternative for gas line connections.

Compression fittings can be used on natural gas lines

5. How to install a compression fitting?

To install a compression fitting, follow these steps:

-

Begin by cutting the tube end cleanly and removing any burrs.

-

Insert the tube into the fitting nut, ensuring it slips past the ferrule(s) until it firmly sits on the internal shoulder of the fitting body.

-

Finger-tighten the nut in a clockwise direction.

-

Mark the nut at the six o’clock position using a marker or grease pen.

-

Hold the fitting body stable with a box wrench.

-

Use another wrench to tighten the nut, seating the ferrules into the tubing securely.

This article by Gas South has provided some highlighted information about compression fittings. We hope to help you understand their mechanisms and applications, including their suitability for natural gas lines, which is crucial for ensuring efficient and safe operations.